Mastering Creality 3D Printing Tips for Exceptional Results

- Creonimus Technology Solutions LLP

- Jan 12

- 3 min read

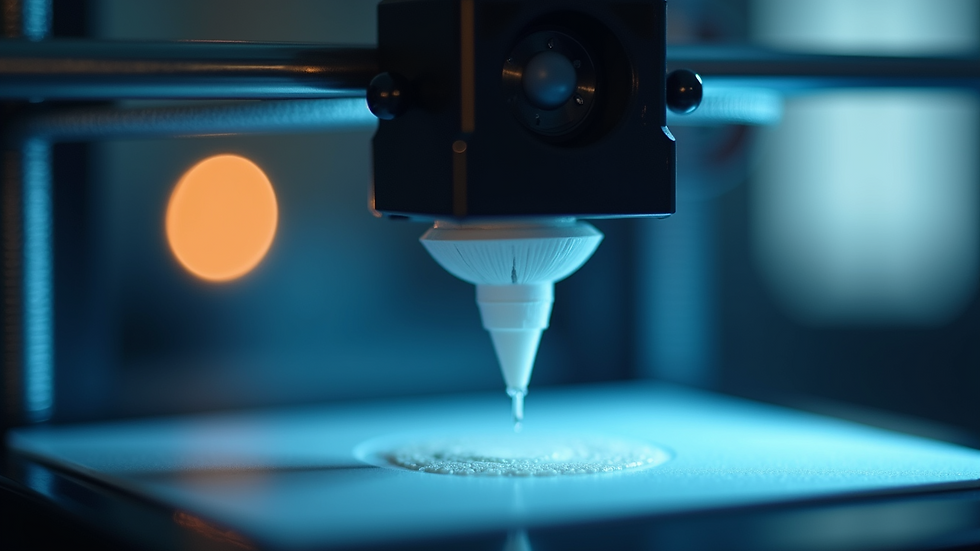

3D printing has revolutionized the way we create prototypes, tools, and even art. Among the many brands available, Creality stands out for its affordability and versatility. Whether you are a beginner or an experienced user, mastering your Creality 3D printer can unlock its full potential and help you produce high-quality prints consistently. This guide will walk you through essential tips and techniques to enhance your 3D printing experience.

Essential Creality 3D Printing Tips for Beginners and Experts

Getting started with a Creality 3D printer can be exciting but also overwhelming. Here are some practical tips to help you get the best results:

Level the Bed Properly: A well-leveled print bed is crucial for adhesion and print quality. Use a piece of paper to check the distance between the nozzle and the bed at multiple points. Adjust the screws until the nozzle just grips the paper.

Use the Right Filament: PLA is great for beginners due to its ease of use and low warping. For more advanced projects, consider ABS or PETG, but be aware of their specific printing requirements.

Optimize Print Settings: Adjust layer height, print speed, and temperature based on your filament and model complexity. Slower speeds and thinner layers usually yield better detail.

Maintain Your Printer: Regularly clean the nozzle, lubricate moving parts, and check belts for tension. This prevents common issues like clogging and layer shifting.

Use Adhesion Aids: Blue painter’s tape, glue sticks, or specialized build surfaces can improve first-layer adhesion and reduce warping.

These tips form the foundation of successful 3D printing with Creality machines.

Advanced Techniques to Enhance Your Creality 3D Printing Experience

Once you have mastered the basics, you can explore advanced techniques to push your printer’s capabilities:

Upgrade Firmware: Installing the latest firmware can improve printer stability and add new features like thermal runaway protection.

Calibrate E-Steps: Ensuring your extruder pushes the correct amount of filament prevents over or under-extrusion, which affects print quality.

Use Supports Wisely: For complex models, supports are necessary but can be tricky to remove. Experiment with support density and pattern to balance ease of removal and print success.

Experiment with Retraction Settings: Fine-tuning retraction distance and speed reduces stringing and blobs on your prints.

Try Different Nozzle Sizes: Smaller nozzles (0.2mm) offer finer detail, while larger nozzles (0.6mm or 0.8mm) speed up printing for bigger parts.

These techniques require patience and testing but can significantly improve your prints.

What is the Creality Controversy?

Creality has gained a massive following, but it has not been without controversy. Some users have raised concerns about:

Quality Control Issues: Early batches of some models had inconsistent parts or assembly problems.

Customer Support: Some customers report slow or unhelpful responses from Creality’s support team.

Firmware and Software Limitations: While Creality provides firmware updates, some users feel the software ecosystem lags behind competitors.

Despite these issues, many users find that the affordability and modifiability of Creality printers outweigh the drawbacks. The community around Creality is active and often provides unofficial fixes and upgrades.

Troubleshooting Common Issues with Creality 3D Printers

Even with the best setup, problems can arise. Here are solutions to frequent issues:

Warping: Use a heated bed, enclosure, or adhesion aids. Lower the cooling fan speed for the first few layers.

Layer Shifting: Check belt tension and pulley set screws. Ensure the printer is on a stable surface.

Stringing: Increase retraction distance and speed. Lower printing temperature slightly.

Under-Extrusion: Clean the nozzle, check filament diameter, and calibrate extruder steps.

Nozzle Clogs: Use high-quality filament and perform regular nozzle cleaning with a cold pull or needle.

Documenting your settings and changes helps identify what works best for your specific printer and filament.

Enhancing Your Prints with Post-Processing Techniques

Post-processing can elevate your 3D prints from functional to professional-looking:

Sanding: Start with coarse grit and move to finer grits to smooth surfaces.

Priming and Painting: Use primer to fill small gaps, then paint with acrylics or spray paint.

Acetone Vapor Smoothing: For ABS prints, acetone vapor can smooth surfaces and add shine.

Assembly and Gluing: Use cyanoacrylate (super glue) or epoxy for strong bonds between parts.

Heat Treatment: Carefully applying heat can relieve internal stresses and improve strength.

These finishing touches make your prints suitable for display, prototypes, or functional parts.

Mastering your Creality 3D printer is a journey of learning and experimentation. By applying these tips and techniques, you can achieve impressive results and enjoy the creative possibilities of 3D printing.

For more detailed guides and community support, explore resources dedicated to creality 3d printers.

Comments