Bambulab Innovation Insights: Precision in 3D Printing

- AYAN GHOSH

- Jan 26

- 3 min read

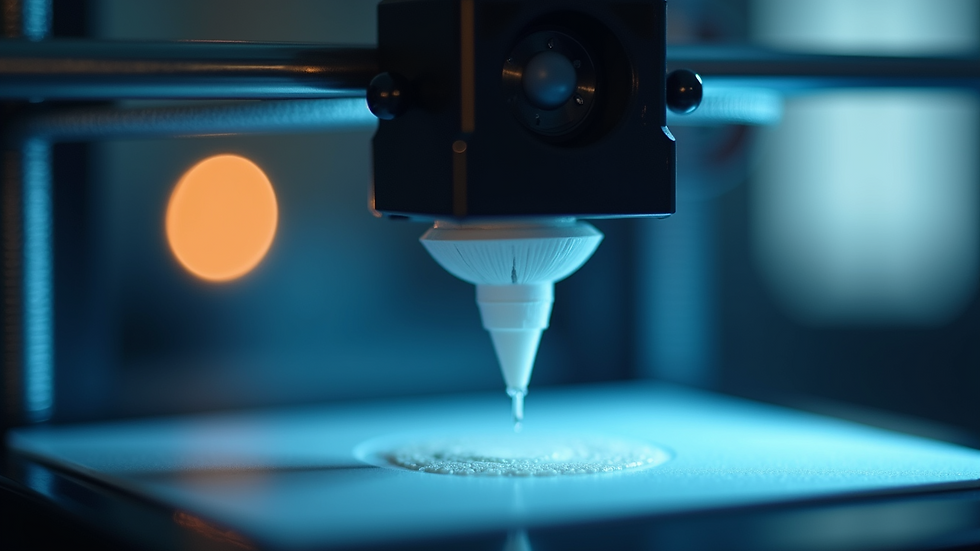

In the rapidly evolving world of 3D printing, precision is paramount. Achieving high accuracy and detail can make the difference between a prototype that works and one that fails. Among the many players in this field, one name stands out for its commitment to precision and innovation. This article explores the key aspects of precision in 3D printing, focusing on the technological advancements and design philosophies that set certain manufacturers apart.

Understanding Precision in 3D Printing

Precision in 3D printing refers to the ability of a printer to reproduce a digital model with exactness and minimal deviation. This involves several factors:

Layer resolution: The thickness of each printed layer, often measured in microns.

Dimensional accuracy: How closely the printed object matches the intended dimensions.

Repeatability: The printer’s ability to produce identical parts consistently.

Surface finish: The smoothness and detail of the printed surfaces.

High precision is essential for applications in engineering, medical devices, and detailed artistic models. It ensures that parts fit together correctly, function as intended, and require minimal post-processing.

Bambulab Innovation Insights: Advancing Precision

One company that has made significant strides in enhancing 3D printing precision is bambulab. Their approach combines cutting-edge hardware with intelligent software to deliver exceptional results.

Hardware Excellence

Bambulab printers are designed with precision components such as:

High-quality linear rails: These provide smooth and stable movement of the print head, reducing vibrations and inaccuracies.

Advanced extruders: Capable of fine filament control, allowing for consistent material flow.

Temperature control systems: Ensuring stable extrusion temperatures for uniform layer adhesion.

These hardware features contribute to achieving layer heights as low as 20 microns, enabling ultra-fine detail in prints.

Software and Calibration

Precision is not just about hardware; software plays a crucial role. Bambulab’s proprietary software includes:

Automatic bed leveling: Ensures the print surface is perfectly aligned, preventing warping and layer misalignment.

Adaptive slicing: Adjusts layer thickness dynamically based on model geometry, optimizing detail and print speed.

Real-time monitoring: Detects and corrects errors during printing to maintain accuracy.

Together, these innovations reduce user intervention and improve print success rates.

Practical Applications of High-Precision 3D Printing

The benefits of precision extend across various industries:

Medical field: Custom prosthetics and surgical guides require exact dimensions to fit patients perfectly.

Engineering prototypes: Functional parts must meet strict tolerances to test mechanical properties.

Jewelry design: Fine details and smooth finishes are critical for aesthetic appeal.

Education and research: Accurate models help in studying complex structures and concepts.

For example, a medical device manufacturer using a high-precision printer can produce patient-specific implants that reduce surgery time and improve outcomes. Similarly, engineers can iterate designs faster with reliable prototypes that closely mimic final products.

Tips for Maximizing Precision in Your 3D Prints

Achieving the best results requires attention to detail beyond just the printer’s capabilities. Here are some actionable recommendations:

Use high-quality filament: Consistent diameter and material properties reduce extrusion issues.

Maintain your printer: Regular cleaning and calibration keep mechanical parts functioning optimally.

Optimize print settings: Adjust speed, temperature, and layer height based on the material and model complexity.

Design for printing: Incorporate features like chamfers and fillets to improve printability and strength.

Post-processing: Techniques such as sanding and polishing can enhance surface finish without compromising detail.

By following these steps, users can fully leverage the precision potential of their 3D printers.

Future Trends in 3D Printing Precision

The quest for greater precision continues to drive innovation. Emerging trends include:

Multi-material printing: Combining different materials in a single print for complex functionality.

AI-driven optimization: Using machine learning to predict and correct printing errors in real time.

Nano-scale printing: Pushing the boundaries of resolution to create microscopic structures.

Improved sensor integration: Enhancing feedback loops for better control over the printing process.

These advancements promise to expand the applications of 3D printing and improve the quality of printed parts even further.

Embracing Precision for Better Outcomes

Precision in 3D printing is not just a technical specification; it is a critical factor that influences the success of projects across industries. By investing in advanced technology and adopting best practices, users can achieve superior results that meet demanding standards.

For those looking to explore high-precision 3D printing, considering manufacturers that prioritize innovation and quality, such as bambulab, can be a game-changer. Their commitment to precision ensures that every print is a step closer to perfection.

This exploration of precision in 3D printing highlights the importance of combining hardware, software, and user expertise to unlock the full potential of additive manufacturing. Whether for professional or creative purposes, precision remains the cornerstone of quality and reliability in 3D printed objects.

Comments