Bambulab Innovation Insights: Precision in 3D Printing

- AYAN GHOSH

- Jan 26

- 3 min read

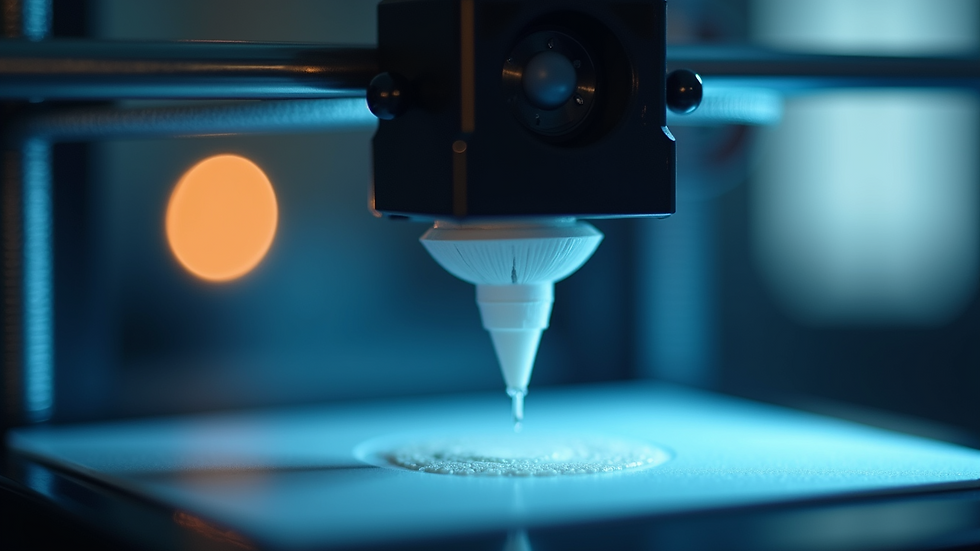

3D printing has revolutionized manufacturing, prototyping, and creative design. Among the many players in this field, one name stands out for its exceptional precision and innovation. This article explores the remarkable accuracy and technological advancements that define Bambulab's approach to 3D printing. Whether you are a hobbyist, engineer, or business owner, understanding these insights can help you leverage 3D printing for your projects.

Understanding Precision in 3D Printing

Precision in 3D printing refers to the ability of a printer to reproduce a digital model with exactness and minimal deviation. It is a critical factor that affects the quality, functionality, and aesthetics of printed objects. High precision means sharper details, smoother surfaces, and better fit for parts that need assembly.

Several factors influence precision:

Printer mechanics: The quality of motors, belts, and rails.

Nozzle size and control: Smaller nozzles can print finer details.

Material properties: Different filaments behave differently during printing.

Software algorithms: Slicing software determines how layers are formed.

Calibration and maintenance: Regular tuning ensures consistent results.

Bambulab has focused on optimizing these elements to push the boundaries of what desktop 3D printers can achieve.

Bambulab Innovation Insights in 3D Printing Technology

Bambulab's innovation insights reveal a commitment to precision through both hardware and software enhancements. Their printers incorporate advanced features such as:

High-resolution stepper motors: These allow for extremely fine movements, reducing layer misalignment.

Auto-calibration systems: Sensors automatically adjust bed leveling and nozzle height, eliminating human error.

Thermal management: Precise temperature control prevents warping and ensures consistent extrusion.

Custom slicing software: Tailored algorithms optimize print paths for smoother finishes and faster print times.

For example, Bambulab's printers can achieve layer heights as low as 0.05 mm, which is exceptional for consumer-grade machines. This level of detail is ideal for intricate models like jewelry prototypes or mechanical parts requiring tight tolerances.

Materials and Their Impact on Precision

The choice of material plays a significant role in the final print quality. Bambulab supports a wide range of filaments, including PLA, ABS, PETG, and specialty materials like flexible TPU and carbon fiber composites. Each material has unique characteristics:

PLA: Easy to print, minimal warping, good for detailed models.

ABS: Stronger and heat-resistant but requires heated bed and enclosure.

PETG: Combines strength and flexibility, less brittle than PLA.

TPU: Flexible, used for parts requiring elasticity.

Carbon fiber composites: Enhanced strength and stiffness for functional parts.

Bambulab's printers are calibrated to handle these materials with precision, adjusting extrusion rates and temperatures automatically. This adaptability ensures that users can experiment with different filaments without sacrificing accuracy.

Practical Tips for Achieving Maximum Precision

To get the best results from a 3D printer like those from Bambulab, consider the following actionable recommendations:

Regular Calibration: Use the printer’s auto-calibration features before every print to ensure the bed and nozzle are perfectly aligned.

Use Quality Filament: Cheap or old filament can cause inconsistent extrusion and clogging.

Optimize Print Settings: Adjust layer height, print speed, and temperature based on the material and model complexity.

Maintain the Printer: Clean the nozzle regularly and check belts and rails for wear.

Design for 3D Printing: Avoid overly thin walls and include supports for overhangs to prevent print failures.

By following these steps, users can maximize the precision capabilities of their 3D printers and produce professional-grade results.

Future Trends in 3D Printing Precision

The future of 3D printing promises even greater precision and versatility. Emerging trends include:

Multi-material printing: Combining different materials in one print for complex functionality.

AI-driven slicing: Artificial intelligence optimizing print paths in real-time.

Nano-scale printing: Achieving microscopic details for medical and electronics applications.

Sustainable materials: Biodegradable and recycled filaments with consistent quality.

Companies like bambulab are at the forefront of integrating these innovations into accessible desktop printers, making high-precision 3D printing available to a broader audience.

Enhancing Your Projects with Precision 3D Printing

Precision in 3D printing opens up new possibilities for creators and professionals alike. Whether you are producing prototypes, custom tools, or artistic pieces, the ability to print with exactness saves time and resources. Investing in a printer that prioritizes precision, like those developed by Bambulab, ensures your projects meet the highest standards.

Explore the capabilities of precision 3D printing and elevate your work to the next level with the right technology and techniques.

Comments