Exploring SLA 3D Printer Applications: A Comprehensive Guide

- Creonimus Technology Solutions LLP

- Jan 18

- 4 min read

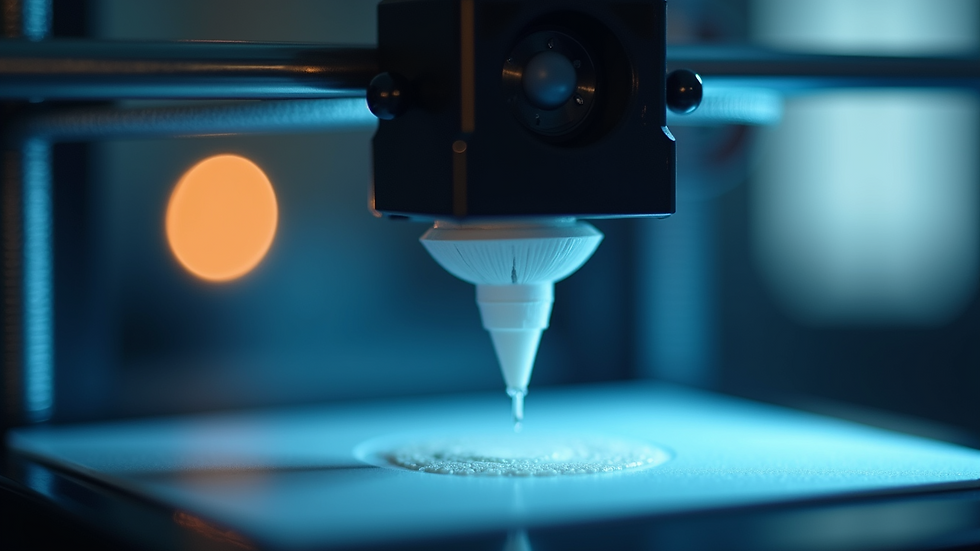

Stereolithography (SLA) 3D printing is a revolutionary technology that has transformed the way prototypes, models, and even end-use parts are created. Unlike traditional manufacturing methods, SLA offers precision, speed, and versatility, making it a popular choice across various industries. This article delves into the world of SLA 3D printer applications, explaining how this technology works, its benefits, and practical uses.

What is SLA 3D Printing?

SLA 3D printing is a form of additive manufacturing that uses a laser to cure liquid resin into hardened plastic in a layer-by-layer process. The laser traces a pattern on the surface of the resin, solidifying it according to the digital design. Once a layer is complete, the build platform moves, allowing the next layer to be formed.

This process results in highly detailed and smooth parts, often with better resolution than other 3D printing methods like Fused Deposition Modeling (FDM). SLA is especially valued for its ability to produce complex geometries and fine features.

Key Components of SLA Printers

Laser Source: Typically a UV laser that initiates the curing process.

Resin Tank: Holds the photopolymer resin.

Build Platform: Moves vertically to allow layer-by-layer construction.

Control System: Manages the laser path and printer operations.

SLA 3D Printer Applications Across Industries

SLA 3D printers have found applications in numerous fields due to their precision and surface finish quality. Here are some of the most prominent uses:

1. Prototyping and Product Development

SLA is widely used for creating prototypes that require high detail and accuracy. Designers and engineers can quickly produce functional models to test form, fit, and function before moving to mass production. This reduces development time and costs.

Example: Automotive companies use SLA to prototype intricate parts like dashboard components or engine parts.

Benefit: Rapid iteration with minimal material waste.

2. Dental and Medical Models

The medical field benefits greatly from SLA technology. Custom dental implants, surgical guides, and anatomical models can be produced with exceptional precision.

Example: Dentists use SLA-printed molds for crowns and bridges.

Benefit: Personalized treatment and improved patient outcomes.

3. Jewelry and Fashion

SLA allows jewelers to create detailed wax patterns for casting, enabling intricate designs that would be difficult to achieve by hand.

Example: Custom rings and bracelets with complex filigree.

Benefit: Faster production and the ability to customize designs easily.

4. Engineering and Manufacturing

SLA parts can be used for functional testing and even as end-use components in some cases. The technology supports the creation of complex tooling, jigs, and fixtures.

Example: Aerospace companies use SLA parts for lightweight components.

Benefit: Reduced lead times and enhanced design flexibility.

How to Choose the Right SLA Printer for Your Needs

Selecting an SLA printer depends on several factors including budget, required resolution, build volume, and material compatibility. Here are some tips to guide your decision:

Resolution and Accuracy: Higher resolution printers are ideal for detailed work like jewelry or dental applications.

Build Volume: Consider the size of the parts you want to print. Larger build volumes allow for bigger models but may come at a higher cost.

Material Options: Different resins offer various properties such as flexibility, toughness, or biocompatibility.

Ease of Use: Look for printers with user-friendly software and reliable customer support.

Post-Processing Requirements: SLA parts often require washing and curing after printing, so factor in the time and equipment needed.

Tips for Optimizing SLA 3D Printing Results

To get the best results from your SLA printer, consider the following recommendations:

Design for SLA: Avoid overly thin walls and ensure proper support structures to prevent print failures.

Use Quality Resin: Invest in high-quality resins suited for your application to improve strength and finish.

Calibrate Regularly: Maintain your printer by calibrating the laser and build platform frequently.

Post-Processing: Properly wash and cure parts to enhance mechanical properties and surface finish.

Monitor Print Environment: Keep the printing area dust-free and maintain stable temperature conditions.

Future Trends in SLA 3D Printing

The future of SLA technology looks promising with ongoing advancements:

Faster Printing Speeds: Innovations like continuous liquid interface production (CLIP) are reducing print times.

New Materials: Development of bioresins and engineering-grade materials expands application possibilities.

Integration with Other Technologies: Combining SLA with CNC machining or injection molding for hybrid manufacturing.

Sustainability: Efforts to create recyclable and less toxic resins.

As these trends evolve, SLA 3D printers will become even more versatile and accessible.

Unlocking the Potential of SLA 3D Printers

Understanding the capabilities and applications of SLA 3D printers opens up numerous opportunities for innovation and efficiency. Whether you are developing prototypes, creating custom medical devices, or producing intricate jewelry, this technology offers unmatched precision and quality.

For those interested in exploring this technology further, consider researching the latest models and materials available in the market. Embracing SLA 3D printing can significantly enhance your design and manufacturing processes.

Explore more about sla 3d printers to stay updated on the latest advancements and applications.

Comments