Exploring SLA 3D Printer Applications: A Comprehensive Guide

- AYAN GHOSH

- Jan 17

- 4 min read

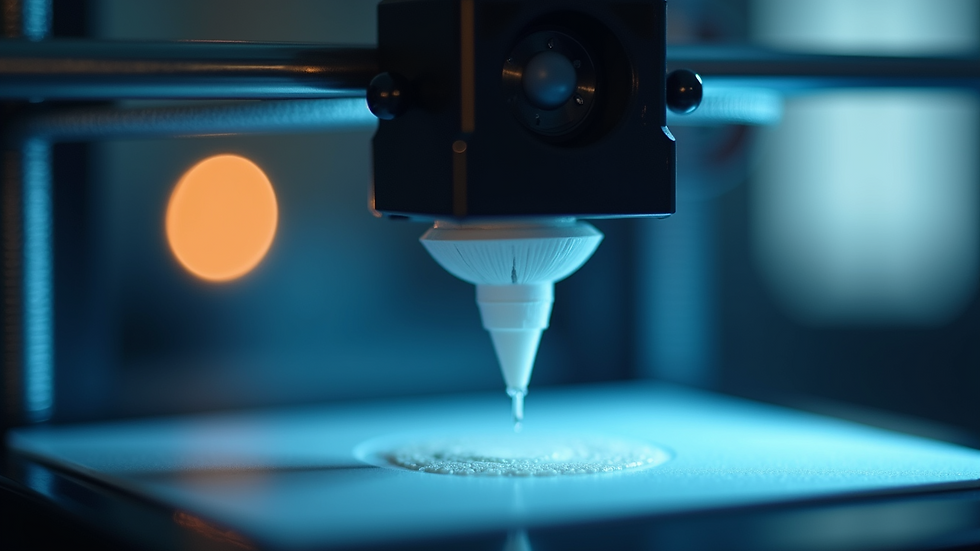

Stereolithography (SLA) 3D printing is a fascinating technology that has transformed the way prototypes, models, and even end-use parts are created. Unlike traditional manufacturing methods, SLA offers precision, speed, and versatility, making it a popular choice across various industries. This article delves into the world of SLA 3D printer applications, explaining how this technology works, its benefits, and practical uses.

What is SLA 3D Printing?

SLA 3D printing is a form of additive manufacturing that uses a laser to cure liquid resin into hardened plastic in a layer-by-layer process. The laser traces a pattern on the surface of a vat filled with photopolymer resin, solidifying the resin where it touches. Once a layer is complete, the build platform moves, allowing the next layer to be formed on top of the previous one.

This process results in highly detailed and smooth parts, often with a resolution far superior to other 3D printing methods like Fused Deposition Modeling (FDM). SLA is especially valued for its ability to produce complex geometries and fine features.

Key Components of an SLA Printer

Laser Source: Typically a UV laser that initiates the curing process.

Resin Vat: Holds the liquid photopolymer resin.

Build Platform: Moves vertically to allow layer-by-layer construction.

Control System: Manages the laser path and printer operations.

SLA 3D Printer Applications in Various Industries

SLA 3D printers have found applications in many fields due to their precision and surface finish quality. Here are some of the most prominent uses:

1. Prototyping and Product Development

SLA is widely used for creating prototypes that require high detail and smooth surfaces. Designers and engineers can quickly iterate designs, test form and fit, and make adjustments before moving to mass production.

Example: Automotive companies use SLA to prototype dashboard components and intricate engine parts.

Benefit: Reduces time and cost compared to traditional prototyping methods.

2. Dental and Medical Models

The medical field benefits greatly from SLA technology. Dentists and surgeons use SLA to produce accurate dental molds, surgical guides, and anatomical models.

Example: Custom dental aligners and crowns are designed using SLA-printed molds.

Benefit: Enhances patient outcomes with personalized treatment plans.

3. Jewelry and Fashion

SLA printers can create highly detailed jewelry prototypes and molds for casting. The smooth finish reduces post-processing time, allowing jewelers to bring designs to market faster.

Example: Intricate ring designs with fine details are printed directly or used to create investment casting molds.

Benefit: Enables rapid design changes and customization.

4. Engineering and Functional Parts

While SLA parts are generally not as strong as those made with other methods, they are suitable for functional testing and small-batch production of complex parts.

Example: Aerospace companies use SLA to produce lightweight components with complex internal structures.

Benefit: Allows for lightweight, optimized designs that are difficult to manufacture traditionally.

How to Choose the Right Resin for Your SLA Project

Selecting the appropriate resin is crucial for achieving the desired properties in your printed parts. Resins vary in terms of strength, flexibility, color, and biocompatibility.

Common Types of SLA Resins

Standard Resin: Good for general-purpose prototyping with smooth finishes.

Tough Resin: Offers higher impact resistance, suitable for functional parts.

Flexible Resin: Mimics rubber-like properties for parts requiring elasticity.

Castable Resin: Burns out cleanly for investment casting in jewelry and dental applications.

Biocompatible Resin: Used for medical devices and dental applications requiring safety standards.

Tips for Resin Selection

Define the part’s purpose: Is it for visual prototyping, functional testing, or end-use?

Consider mechanical properties: Strength, flexibility, and durability.

Check compatibility: Ensure the resin works with your specific SLA printer model.

Post-processing needs: Some resins require additional curing or washing steps.

Best Practices for Optimizing SLA Prints

To get the most out of your SLA 3D printer, follow these actionable recommendations:

Design with support structures in mind: SLA prints often need supports to prevent warping or collapse during printing.

Orient parts strategically: Position parts to minimize supports and improve surface finish.

Use proper post-processing: Clean parts in isopropyl alcohol and cure under UV light to enhance strength.

Maintain your printer: Regularly check the resin vat and laser calibration for consistent results.

Experiment with layer thickness: Thinner layers improve detail but increase print time.

Future Trends in SLA 3D Printing

The technology behind SLA 3D printing continues to evolve, with exciting developments on the horizon:

Faster printing speeds: New laser systems and resin formulations aim to reduce print times.

Multi-material printing: Combining different resins in one print for complex functionality.

Larger build volumes: Expanding the size of printable parts for industrial applications.

Sustainability: Development of eco-friendly resins and recycling methods.

These advancements will broaden the scope of SLA 3D printer applications, making the technology even more accessible and versatile.

Unlocking the Potential of SLA 3D Printers

Understanding the capabilities and applications of SLA 3D printers opens up numerous possibilities for innovation and efficiency. Whether you are creating detailed prototypes, medical models, or functional parts, this technology offers precision and quality that few other methods can match.

For those interested in exploring this technology further, consider investing in a reliable sla 3d printers model that fits your specific needs. With the right equipment and materials, you can harness the power of SLA to bring your ideas to life with exceptional detail and accuracy.

Comments