CTS3D: Advanced 3D Printing Solutions for Your Needs

- Creonimus Technology Solutions LLP

- Sep 23, 2025

- 3 min read

3D printing technology has revolutionized the way products are designed, prototyped, and manufactured. Whether you are an entrepreneur, engineer, or hobbyist, having access to reliable and advanced 3D printing services can make a significant difference in bringing your ideas to life. This article explores the cutting-edge solutions offered by CTS3D printing services and how they can meet diverse project requirements with precision and efficiency.

Exploring CTS3D Printing Services for Diverse Applications

CTS3D printing services provide a comprehensive range of options tailored to various industries and project scales. From rapid prototyping to small-batch production, their expertise covers multiple 3D printing technologies such as FDM, SLA, and SLS. These technologies allow for the creation of parts with different materials, finishes, and mechanical properties.

For example, if you need a durable prototype for functional testing, CTS3D can produce parts using high-strength thermoplastics. On the other hand, for highly detailed models or visual presentations, resin-based SLA printing offers smooth surfaces and intricate details. This flexibility ensures that clients receive the best possible outcome for their specific needs.

Key benefits of CTS3D printing services include:

Fast turnaround times to accelerate product development cycles

Access to a variety of materials including plastics, resins, and composites

High precision and repeatability for consistent quality

Custom finishing options such as painting, sanding, and assembly

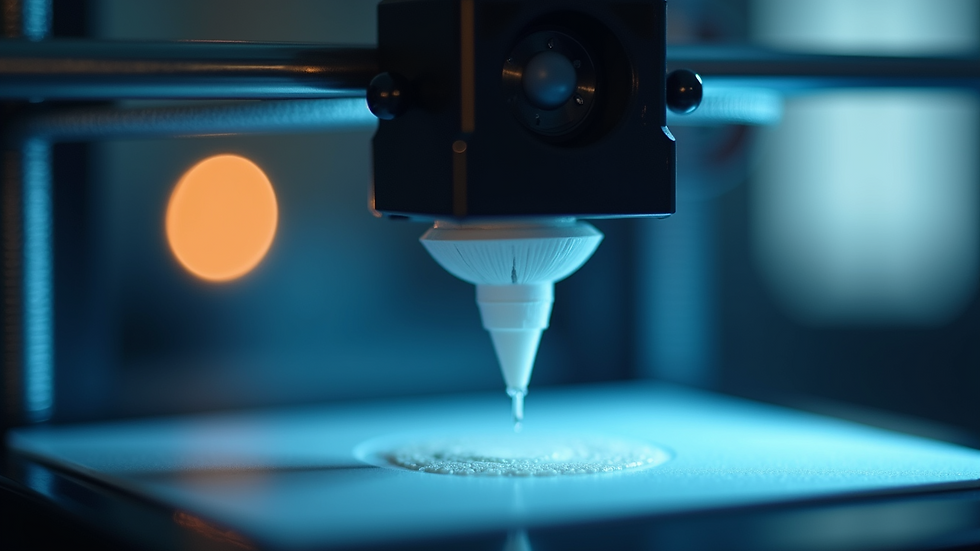

Close-up of a 3D printer nozzle producing a detailed plastic prototype

How CTS3D Printing Services Enhance Product Development

One of the most valuable aspects of advanced 3D printing services is their ability to streamline product development. By using CTS3D, designers and engineers can quickly iterate on their concepts without the need for expensive tooling or long lead times. This iterative process helps identify design flaws early and optimize functionality before mass production.

For instance, a startup developing a new consumer gadget can order multiple versions of a prototype with slight variations. This allows for hands-on testing and user feedback, which can be incorporated into the next design iteration. The result is a refined product that meets market demands more effectively.

Additionally, CTS3D printing services support complex geometries that traditional manufacturing methods struggle to achieve. This opens up new possibilities for lightweight structures, internal channels, and customized parts that improve performance and reduce material waste.

Eye-level view of a 3D printed mechanical part showcasing intricate internal structures

Materials and Technologies Offered by CTS3D Printing Services

Understanding the materials and technologies available is crucial when selecting a 3D printing service. CTS3D offers a diverse portfolio to suit different project requirements:

Fused Deposition Modeling (FDM)

Uses thermoplastic filaments like ABS, PLA, and Nylon

Ideal for functional prototypes and durable parts

Cost-effective and widely accessible

Stereolithography (SLA)

Utilizes photopolymer resins cured by UV light

Produces high-resolution parts with smooth finishes

Suitable for detailed models and molds

Selective Laser Sintering (SLS)

Employs laser to sinter powdered materials such as nylon

Creates strong, complex parts without support structures

Great for functional end-use components

Each technology has its strengths, and CTS3D experts help clients choose the best option based on factors like mechanical properties, surface finish, and budget. This consultative approach ensures optimal results for every project.

High angle view of a 3D printer bed producing multiple parts simultaneously

Practical Tips for Maximizing Your 3D Printing Project Success

To get the most out of CTS3D printing services, consider these actionable recommendations:

Prepare your 3D model carefully: Ensure your design files are clean, watertight, and optimized for the chosen printing technology. Use software tools to check for errors and adjust wall thicknesses.

Communicate your requirements clearly: Provide detailed specifications including material preferences, color, finish, and intended use. This helps the service provider tailor the process accordingly.

Request prototypes before final production: Ordering a prototype allows you to verify fit, function, and aesthetics. It reduces the risk of costly mistakes in larger production runs.

Leverage finishing services: Post-processing like sanding, painting, or assembly can enhance the appearance and usability of your parts. Discuss these options upfront.

Plan for lead times: While 3D printing is fast, complex or large orders may require additional time. Coordinate your project timeline with the service provider to avoid delays.

By following these tips, you can ensure a smooth experience and high-quality results from your 3D printing projects.

Unlocking Innovation with CTS3D Printing Services

The future of manufacturing is increasingly digital and customizable. CTS3D printing services empower innovators to push boundaries and create products that were once impossible or too costly to produce. Whether you are developing prototypes, custom tools, or end-use parts, their advanced capabilities provide a competitive edge.

Explore how cts3d can support your next project with expert guidance, cutting-edge technology, and reliable service. Embrace the possibilities of 3D printing and transform your ideas into reality with confidence.

This comprehensive overview highlights the value of advanced 3D printing solutions and practical advice to help you succeed. With the right partner and approach, your creative potential is limitless.

Comments