3D Printed Titanium Implants: Revolutionizing Healthcare

- Swarnadip Dutta

- Apr 7, 2024

- 3 min read

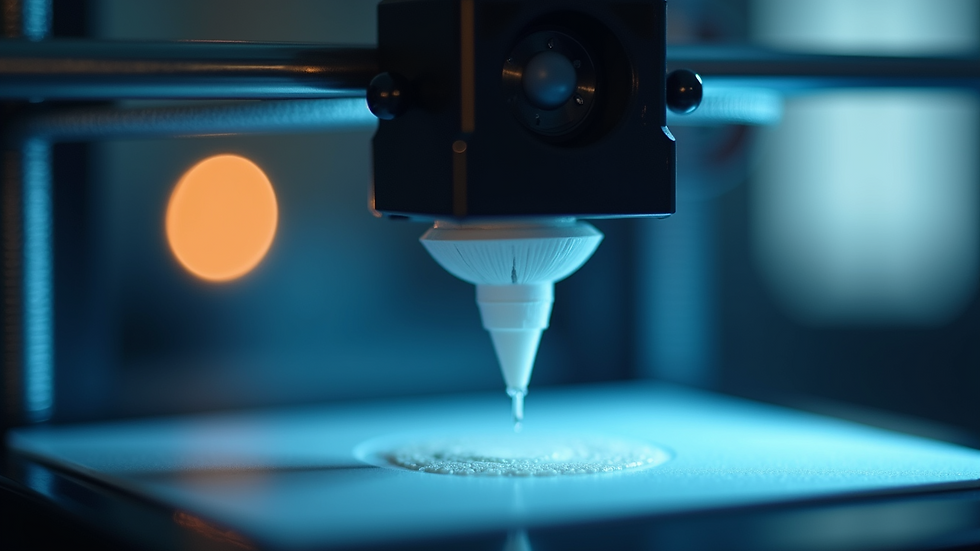

In the realm of medical innovation, one technological marvel stands out prominently: 3D printed titanium implants. This cutting-edge advancement has revolutionized healthcare by offering tailored solutions for patients in need of implants. From dental fixtures to orthopedic implants, the application of 3D printing in medicine has opened doors to unprecedented levels of customization, precision, and patient-specific care.

Unveiling the Power of 3D Printing in Medicine

Traditional manufacturing processes for medical implants often involve extensive machining, casting, or forging, resulting in standardized products that may not perfectly fit individual patients. However, with the advent of 3D printing, a paradigm shift has occurred. This additive manufacturing technique enables the creation of intricate and personalized implants with unparalleled accuracy.

The Role of Titanium: A Material of Choice

Titanium's biocompatibility, corrosion resistance, and exceptional strength-to-weight ratio make it an ideal material for medical implants. By utilizing 3D printing technology, titanium implants can be fabricated layer by layer, allowing for intricate designs and structures that were previously impossible to achieve using conventional methods.

Customization: Tailoring Implants to Individual Needs

One of the most significant advantages of 3D printed titanium implants lies in their customization capabilities. Medical professionals can now design implants that precisely match the anatomical requirements of each patient. Whether it's a dental crown, a hip replacement component, or a spinal fusion cage, these implants can be tailored to fit perfectly, reducing the risk of complications and improving patient outcomes.

Precision Engineering: Enhancing Implant Performance

The precision offered by 3D printing technology ensures that implants are manufactured with utmost accuracy. This level of precision not only enhances the fit and functionality of the implants but also allows for the incorporation of features such as porous structures for improved osseointegration and surface textures to promote tissue adhesion.

Applications Across Medical Specialties

The versatility of 3D printed titanium implants transcends various medical specialties, offering innovative solutions for a wide range of conditions.

Orthopedics: Restoring Mobility and Functionality

In orthopedic surgery, titanium implants play a vital role in restoring mobility and functionality to patients with joint disorders or fractures. Whether it's a knee replacement, a shoulder implant, or a spinal fusion device, 3D printed titanium implants offer durable and precisely-fitted solutions that mimic the natural anatomy, leading to improved patient satisfaction and long-term outcomes.

Dentistry: Transforming Smiles with Precision

In the field of dentistry, 3D printed titanium implants have revolutionized tooth restoration procedures. From dental crowns and bridges to dental implants, these customized solutions ensure optimal aesthetics and functionality while preserving the surrounding healthy tissue. Moreover, the biocompatibility of titanium minimizes the risk of adverse reactions, making it an ideal choice for dental applications.

Maxillofacial Surgery: Reconstructing Facial Structures

For patients requiring maxillofacial reconstruction due to trauma, congenital defects, or tumor resection, 3D printed titanium implants offer a lifelike solution. By precisely replicating the patient's facial anatomy, these implants restore both form and function, providing patients with improved quality of life and self-esteem.

Future Directions and Challenges

While 3D printed titanium implants have undoubtedly transformed the landscape of modern medicine, ongoing research aims to further enhance their capabilities. Advancements in materials science, bioengineering, and 3D printing technology hold the promise of even more personalized and biologically optimized implants in the future.

However, challenges such as regulatory approval, cost-effectiveness, and scalability remain hurdles to widespread adoption. Addressing these challenges requires collaboration between researchers, clinicians, industry stakeholders, and regulatory agencies to ensure that patients benefit from the full potential of this groundbreaking technology.

The advent of 3D printed titanium implants represents a significant milestone in healthcare innovation. By combining the precision of 3D printing with the biocompatibility of titanium, these implants offer tailored solutions that improve patient outcomes across various medical specialties. As technology continues to evolve, the future of medicine looks brighter than ever, with 3D printed titanium implants leading the way towards personalized, precise, and patient-centric care.

Credits - Eplus3D, HeroX, All3DP

Comments