3D Printed Molds: Exploring the Evolution of Manufacturing

- Swarnadip Dutta

- Feb 17, 2024

- 2 min read

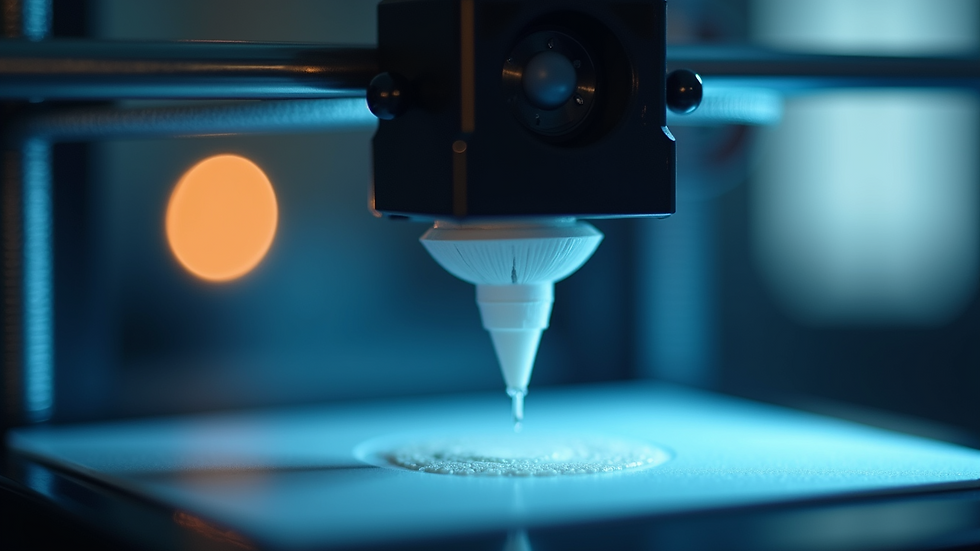

In the realm of manufacturing, innovation knows no bounds. Enter 3D printed molds, a groundbreaking advancement that is reshaping the way products are fabricated across industries. In this article, we delve into the transformative potential of 3D printed molds, exploring their benefits, applications, and the future of manufacturing.

Revolutionizing Production Processes with 3D Printed Molds

Traditional mold manufacturing methods often entail labor-intensive processes, long lead times, and limited design flexibility. However, the emergence of 3D printing technology has revolutionized the production landscape by offering a more agile and efficient alternative.

1. Design Freedom and Customization

3D printed molds empower manufacturers with unparalleled design freedom and customization capabilities. Complex geometries and intricate details that were once challenging to achieve with conventional methods are now easily attainable through additive manufacturing. This flexibility enables the production of highly customized and intricate parts with ease.

2. Rapid Prototyping and Iteration

The iterative nature of product development demands quick turnaround times for prototypes and design iterations. With 3D printed molds, manufacturers can expedite this process by rapidly producing molds directly from digital designs. This accelerated prototyping cycle reduces time-to-market and enables faster product iterations, ultimately driving innovation.

3. Cost-Effective Production

Traditional mold manufacturing involves significant upfront costs associated with tooling and machining. In contrast, 3D printed molds require minimal tooling and setup, resulting in cost savings for manufacturers. Moreover, the ability to consolidate multiple parts into a single 3D printed mold further reduces material waste and production costs.

Diverse Applications Across Industries

The versatility of 3D printed molds extends across a wide range of industries, from automotive and aerospace to consumer goods and medical devices. Whether it's creating intricate components, producing customized prototypes, or streamlining production processes, 3D printed molds offer endless possibilities.

1. Automotive Industry

In the automotive sector, 3D printed molds facilitate the rapid prototyping of vehicle components and custom parts. Manufacturers can quickly iterate on designs and test new concepts without the time and expense associated with traditional tooling methods. This agility enables automotive companies to stay ahead in a competitive market landscape.

2. Consumer Goods and Electronics

From consumer electronics to household appliances, 3D printed molds enable manufacturers to meet evolving consumer demands for personalized products. Whether it's custom smartphone cases or bespoke kitchen gadgets, the ability to create unique designs quickly and cost-effectively gives companies a competitive edge in the marketplace.

3. Medical Device Manufacturing

In the medical industry, precision and customization are paramount. 3D printed molds enable medical device manufacturers to produce patient-specific implants, prosthetics, and surgical instruments with unmatched accuracy and efficiency. This personalized approach to manufacturing enhances patient outcomes and revolutionizes healthcare delivery.

Embracing the Future of Manufacturing

As technology continues to advance, the potential of 3D printed molds in revolutionizing manufacturing processes is limitless. From enhancing design flexibility and accelerating prototyping to enabling cost-effective production across industries, 3D printed molds represent a paradigm shift in the way we approach manufacturing. In conclusion, the adoption of 3D printed molds heralds a new era of innovation and efficiency in manufacturing. By leveraging the power of additive manufacturing, companies can unlock new opportunities for creativity, customization, and competitiveness in a rapidly evolving global market. As we embrace the future of manufacturing, the journey of 3D printed molds promises to be one of continual advancement and transformation.

Comments